SPC "Armastek" LTD ▶︎ Manufacturing of composite reinforcement

Manufacturing of composite reinforcement

Armastek offers equipment of new generation for the production of glass and basalt composite materials.

The equipment is produced on our own patented technology, using advanced domestic and foreign developments. The production experience of our company is more than 10 years. Our engineering staff constantly improves and develops manufacturing technologies. The equipment offered for delivery is produced under the trade mark ARMASTEK.

If you order our equipment, you also receive comprehensive services for the setup of production:

– production technology (recipe, quality manual, process regulations, etc.);

– list of recommended suppliers of raw materials;

– recommendations on the selection of premises, ventilation;

– installation and start-up and maintenance work;

– training;

– assistance in obtaining certificates and conducting tests;

– consultation of technical specialists of our company;

– warranty and after-sales service.

By assembling the lines we use high-quality components from leading manufacturers. Long-term experience of manufacturing confirms 100% efficiency of our equipment. If you want, you can personally verify this by visiting our production site.

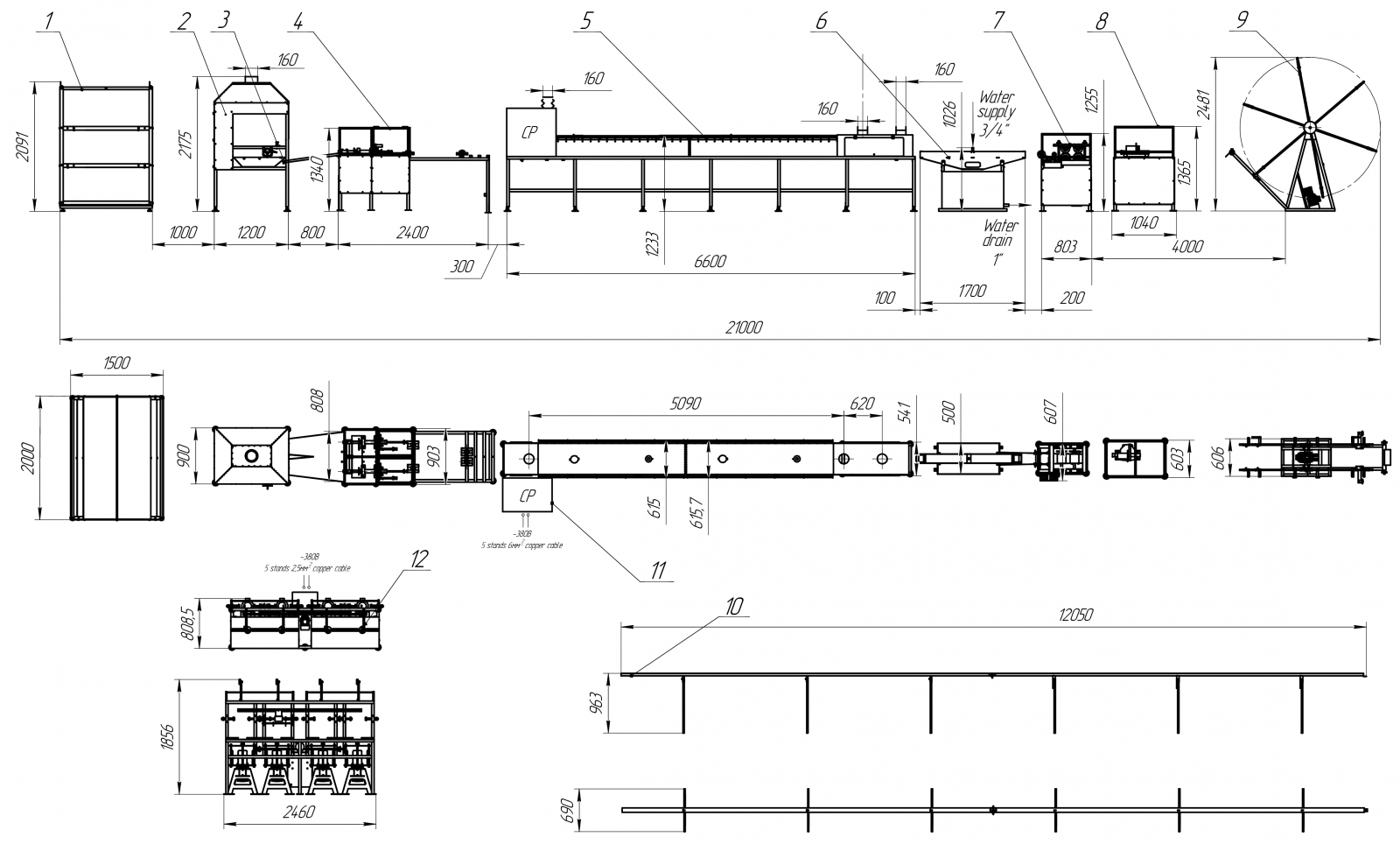

Our production line is designed for the production of composite reinforcement (both glass and basalt fiber) with a diameter of 3 to 30 mm.

Main characteristics of the line:

Operating voltage: 380 V / 50-60 Hz;

Electricity consumption: 11.5 kW;

Overall dimensions of the line (d / w / h): 17 / 0,8 / 2 m;

Available diameters: 3-30 mm;

Output capacity: 2-10 pm / min.

The offered Armastek line allows to produce up to 2 bars of reinforcement at the same time. Released reinforcement has a constant cross section, with a frequent winding angle, which ensures the strength of the connection of reinforcement with concrete by 15-20% more than with composite reinforcement manufactured using traditional technology.

Requirements for industrial premises:

– Recommended length of the room: from 40 m;

– Recommended ceiling height in the room: from 3 m;

– The air temperature in the room is not lower than 15 ° С;

– Since during the operation of the line the side gaseous emission from the curing of the polymer and the cutting of the reinforcement (profile) occurs, in order to organize the safe operation of personnel, ventilation is required in the production room, which ensures normal air exchange and dust and smoke removal.

Сircuit design of the line

The equipment consists of the following units and assemblies:

1. Roving rack;

2. Drying unit;

3. Impregnation unit;

4. Forming unit with winder;

5. Polymerization chambers;

6. Cooling bath;

7. Pulling unit;

8. Cutting unit;

9. Coiling unit;

10. Table for finished product in bars;

11. Control panel;

12. Thread twister.

The following materials are used in the manufacturing of reinforcement:

– Roving (glass, basalt);

– Binder components based on epoxy-diane resins.

In composite reinforcement roving takes on mechanical loads, and the binder is a matrix that protects the reinforcement from the effects of the external environment.

Our company:

* Provides consulting assistance:

– for the optimal choice of premises;

– on location of communications in production.

* Provides assistance in passing product tests, obtaining a GOST certificate for products with audit of production site.

* Provides a package of documents necessary to comply with production standards and the passage of all state. supervisory authorities.

The cost of the equipment already includes:

– supervised installation of equipment;

– starting-up and adjustment works (with working off of technological process);

– production recipe;

– training.

Cost of the line:

the price is contractual

For more information, please contact us by phone + 7 (964) 190 25 98 or by mail pav@armastek.net

ALWAYS IN TOUCH

Our managers will help to make the right choice and answer your questions