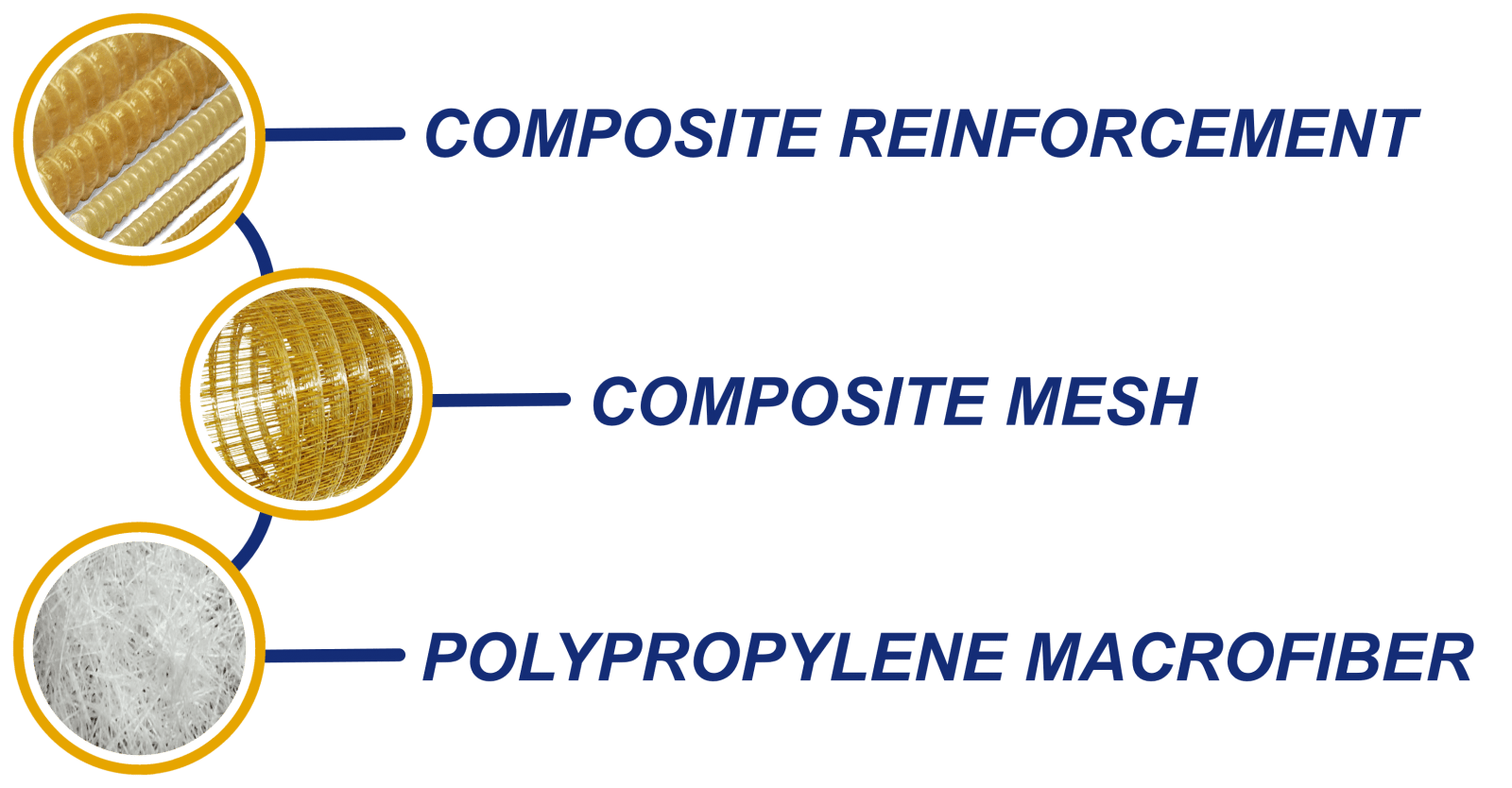

SPC "Armastek" LTD ▶︎ Manufacturing of composite mesh

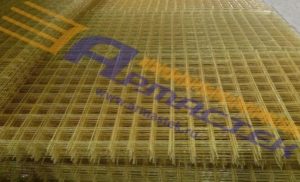

Manufacturing of composite mesh

The equipment is produced on our own patented technology, using advanced domestic and foreign developments. The production experience of our company is more than 10 years. Our engineering staff constantly improves and develops manufacturing technologies. The equipment offered for delivery is produced under the trade mark ARMASTEK.

“Armastek” equipment means:

– a developed and tested technology;

– high-quality product;

– world experience;

– quality equipment;

– product durability.

The offered equipment enables to produce mesh with:

– 500 to 2000 mm width;

– 50×50 / 100×100 / 150*150 / 200*200 mm cell;

– 1.8 to 8.0 mm bar diameter.

Raw materials for production of mesh on the lines of “Armastek”:

– fiber (glass, basalt roving);

– medium;

– compound based on epoxy-diane or polyester resins.

Form of issue:

rolls | sheets |

The complex offer (“plug-and-produce”) includes:

– Production lines;

– A complete set of production documentation necessary for the organization and operation of production;

– Training of your working staff of “Armastek” technology;

– Starting-up and adjustment including the optimization of the technological process and the release of the first meters of mesh by our specialists in the installation of the lines;

– Assistance in passing product tests, obtaining a certificate for products with audit of production.

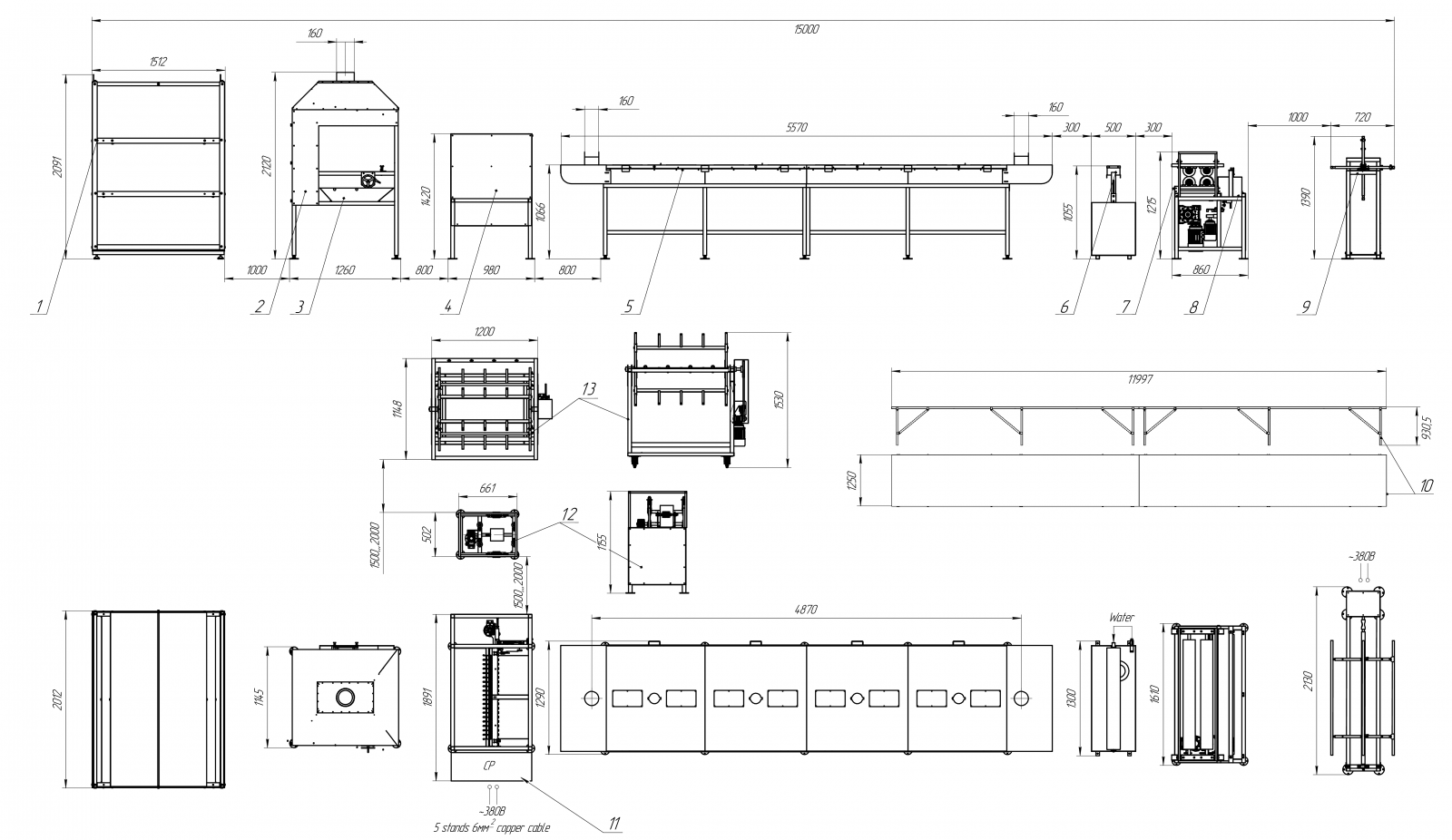

Сircuit design of the line

The equipment consists of the following units and assemblies:

1. Roving rack;

2. Drying unit;

3. Impregnation unit;

4. Splicing unit;

5. Polymerization chambers;

6. Cooling bath;

7. Pulling unit;

8. Cutting unit;

9. Coiling unit;

10.Table for finished product in mesh;

11. Control panel;

12. Prefeeding pulling unit for cross-section bar;

13. Winder and unwinder of coils with cross-section bar.

Specifications

| № | Parameter name | Parameter value |

| 1 | Electricity consumption at start-up within 20 minutes | 30 kW / h |

| 2 | Electricity consumption at constant line operation | 5-6 kW / h |

| 3 | Type of mains current | Alternate three-phase |

| 4 | Voltage | 380 V |

| 5 | Number of motors on line | 5 |

| 6 | The allowed amount of rejects | 1-2% |

| 7 | Comfort operating temperature | +20+25C° |

| 8 | Humidity | <80% |

| 9 | Consumption of cold water | 0.3 m³ / h per line |

| 10 | Closed cycle | Cooler |

| 11 | Minimum rod section of the reinforcing mesh | 1,8 mm |

| 12 | Maximum rod section of the reinforcing mesh | 8 mm |

| 13 | Capacity | 800-1000 square meters / shift (12 hours) |

Dimensional Specifications

| № | Parameter name | Parameter value |

| 1 | Overall dimensions (Length / Width / Height), m | 18,0 * 2,5 * 1,5 |

| 2 | Dimensions, including the roll-facing unit, m | 25,0 * 2,5 * 1,5 |

| 3 | Dimensions, including a table for 12 meter sheets, m | 35,0*2,5* 1,5 |

| 4 | Distance between lines, m | 2 |

| 5 | Area for storage of raw materials | 100 m² |

| 6 | Area for cutting | 200 m² |

| 7 | Area of storage warehouse of products | 300 m² |

| 8 | Area of laboratory, preparation and mixing of raw materials | 30 m² |

ALWAYS IN TOUCH

Our managers will help to make the right choice and answer your questions